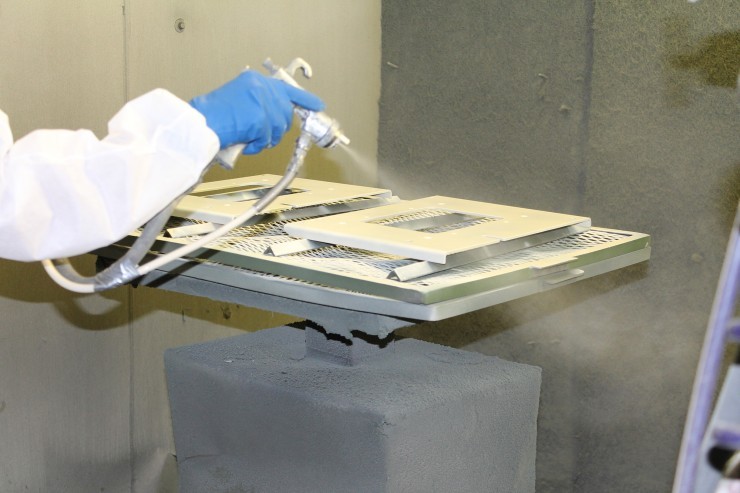

Rhinehart Finishing offers customers a variety of industrial finishing options. Whether your components are large or small, metal or plastic, we can offer complete parts painting services. We provide military-approved CARC coatings as well as commercial powder coatings. Our zinc phosphate pretreatment is certifiable to TT-C-490, Type 1 and provides our military and commercial customers the confidence that their products receive the best pretreatment available for industrial metal coatings. Our largest product overhead window size is 12' x 3' x 6', making Rhinehart Finishing the one place customers can go for all their professional metal finishing needs.

The dimensions for the “overhead” liquid line and powder line are both 12’ x 3’ x 6’. The “Flat Line” dimensions are 8’ x 3’ x 3’. We can also paint in a batch mood in the “Flat Line” and those dimensions are 6’ x 6’ x 6’. Please feel free to contact us with any further questions about our coating services.

Integrated Fabrication-to-Finishing Workflow

Our operations are located right next door to our sister company, Rhinehart Development. Our proximity to a full-service, ISO-9001:2015-certified metal fabrication and stamping facility means we can provide you with end-to-end services for fabrication and finishing. Choosing us to be your one-stop shop means you can forget about dealing with third-party shipping delays, handling risks or overly complex project management requirements.

OEMs, military contractors and commercial manufacturers value our ability to provide streamlined, cost-effective and high-quality production workflows. In addition, having both phases of production provided by the same team means you can trust us to follow coordinated standards and processes throughout your project. This leads to exceptional quality assurance and greater consistency in the finished products.

Finishing Capabilities at a Glance

When it comes to providing the most finishing capabilities under one roof, there’s no better choice than Rhinehart Finishing. Our status as a ISO 9001:2015-certified and TACOM-approved coating provider for combat-grade coatings mean there’s virtually no limit to the metal finishing services we can provide for your project.

We’re trusted by manufacturers across multiple sectors to handle their components in the most appropriate and effective manner possible. From aerospace and defense to heavy trucks and construction equipment, Rhinehart Finishing is the contractor to turn to when you need the highest levels of quality and protection for your components.

Our ISO 9001 metal finishing capabilities include:

- Zinc phosphate pretreatment (for TT-C-490-compliant coatings)

- Industrial powder coating services using epoxy, polyester, and hybrid formulations

- Liquid spray painting in 10 environmentally controlled booths

- Military spec coatings and CARC paint applications including MIL-DTL-64159 and MIL-DTL-53039 coatings

- Batch coating process and conveyorized coating systems (12’ x 3’ x 6’ overhead; 6’ x 6’ x 6’ batch)